Pilot 001 - Trace, Issue, Share, and View

Sponsor: RMI | Phase: 1 | Date: May 2025

The RBTP Knowledge Base is evolving weekly as part of our pilot programs with RBA members. We’d love your input — submit feedback or help shape the protocol in real time by joining a pilot.

1. Overview

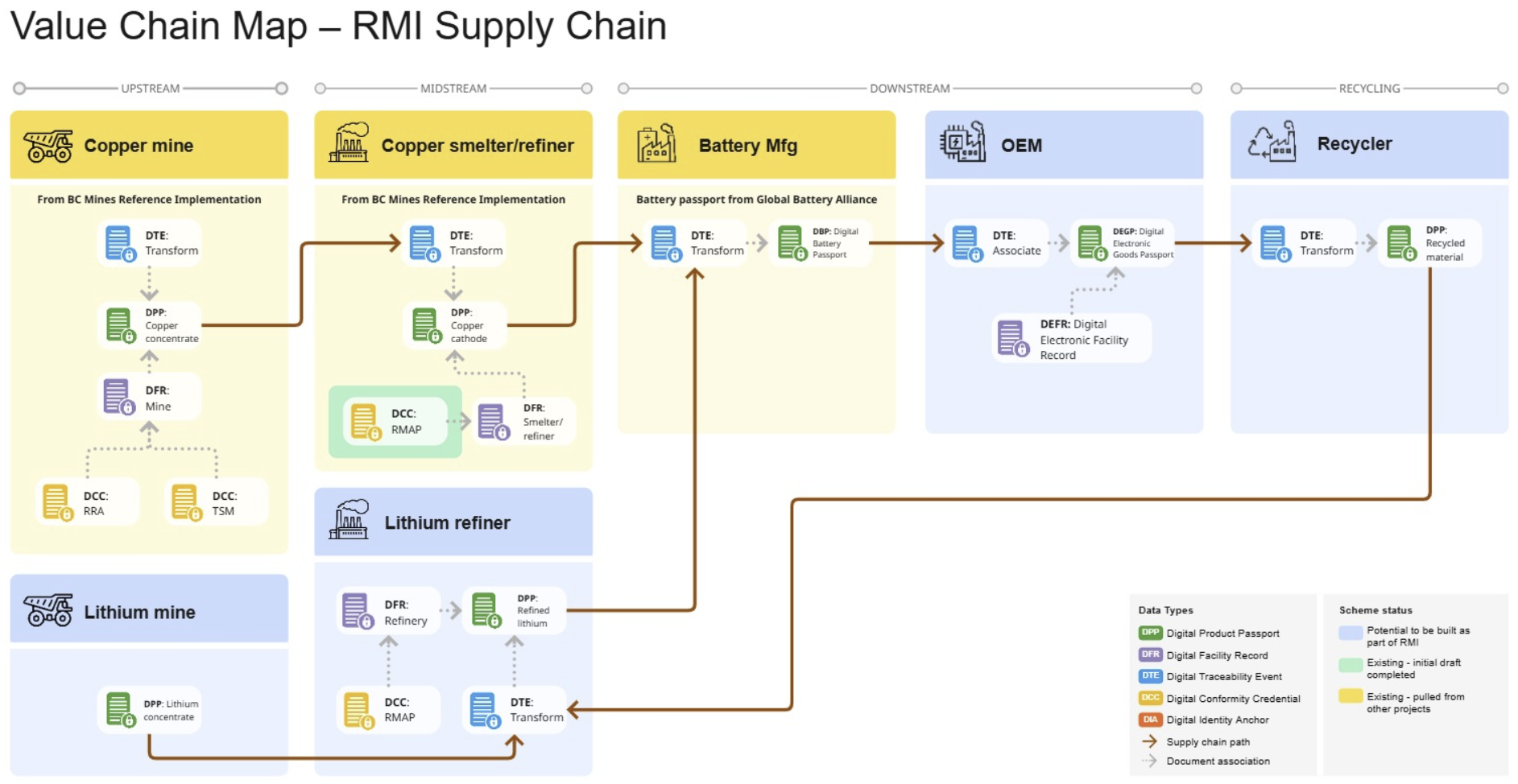

Phase 1 of Pilot 001 demonstrated end-to-end, n-tier traceability using the RBTP Reference Implementation (RI). RMI participants followed digital credentials “from product to mine,” gaining hands-on experience tracing, issuing, sharing, and viewing supply-chain data.

Key Question:

How can I trace the materials in my manufactured part back through multiple tiers to the source mine and verify that RBTP supports n-tier traceability?

Answer:

- Interactive Value-Chain Map Modelled a segment of the chain with multiple upstream sources and hops.

- Guided Demonstration Walked users from an OEM’s Digital Product Passport—through Transformation Events and Digital Facility Records—to the originating mines.

2. Objectives

- Demonstrate core Reference Implementation functions via Interactive Value-Chain Map exercises—e.g. tracing product materials upstream to source mines

- Introduce the Reference Implementation tools through hands-on activities simulating real-world credential workflows—issuing, sharing, and viewing credentials

- Highlight business value by mapping product and facility claims (Digital Conformity Credentials) to Digital Facility Records and Digital Product Passports

3. Deliverables

Interactive Value Chain Map

Credential Catalog

| Credential Type | Examples |

|---|---|

| Facility Records (DFR) | - Core UNTP DFR: Mine, Smelter, Refiner - DEFR Extension: Digital Electronic Facility Record (OEM) |

| Product Passports (DPP) | - Core UNTP DPP: Copper Concentrate, Copper Cathode, Cobalt Concentrate, Refined Cobalt, Recycled Material - DPP Extension: Digital Battery Passport - DPP Extension: Digital Electronic Facility Record |

| Traceability Events (DTE) | - Transaction (Core UNTP – Sales) - Transform (Core UNTP – Smelting, Manufacture, Recycle) - Association (Core UNTP – Assembly) |

| Conformity Credentials (DCC) | - RMAP (Core UNTP – Responsible Minerals Assurance Process) - TSM (Core UNTP – Total Sustainable Mining) - RRA (Core UNTP - Risk Readiness Assessment performed by Coppermark) |

Published Exercises

| Step | Description |

|---|---|

| Trace | Follow the OEM’s Digital Product Passport back to the source mines |

| Issue | Publish a Digital Product Passport |

| Share | Share Product Passports with others |

4. Scope & Supply-Chain Actors

For this Phase 1 pilot, we defined a representative chain of seven actor types and generated synthetic credentials for each:

- Mine A (Copper; BCMines)

- Mine B (Lithium; Synthetic Facility)

- Smelter (Copper → cathode; BCMines)

- Refinery (Lithium + recycled; Synthetic Facility)

- Battery Manufacturer (Battery assembly; Synthetic Facility)

- OEM (Electronic-goods assembly; Synthetic Facility)

- Recycler (End-of-life goods → refinery feed; Synthetic Facility)

5. Phase 1 Pilot Process

| Step | Description |

|---|---|

| Scoping Discussion | Defined supply-chain segment and downstream disclosure requirements; confirmed “Trace, Issue, Share, and View” focus |

| SC Mapping Workshop | Refined supply-chain map; identified actors & credential types; populated map with synthetic data |

| Credential Development | Created synthetic Facility Records, Product Passports, Transformation Events, and Conformity Credentials |

| Demonstration and Published Exercises | Trace, Issue, Share, View Exercises published in the Reference Implementation Guides and Support section of the Knowledge Base. |

6. Next Steps

- Iterate & Refine: Incorporate feedback to enhance credential definitions and map granularity

- Phase 2 Planning: Identify candidate members for light-integration tests

- Tooling Enhancements: Leverage AI-driven workflows (e.g., CDS tool) for accelerated credential generation